G500 - Entry Into Service (EIS)

Updated: Feb 21, 2020

I had — emphasize "had" — a recurring nightmare that the day we first brought our new, shiny G500 to our hangar we would find out the airplane doesn't fit. When I was first asked to consider the airplane, I got myself a 125' tape measure and measured. We have a 95 feet, 1 inch gap when our hangar doors are fully open. Our G450 fit without a problem. But a G500 is (87'1" - 77'4") = 9'9" wider. So, theoretically we only have (95'1" - 87'1") / 2 = 4' on each wing. Theoretically.

Along the way I had a stripe painted right down the middle of the hangar. And then just outboard of each main gear. I sent everyone to marshaling school. We instituted very strict wing walking procedures: hand on the wing, other hand stretched out, driver stops as mains cross threshold, each wing walker verbally confirms clearance. But still the nightmares persisted. But today we brought her in. Four feet on each wing to spare.

The first thing we did was do three takeoffs and landings for one of our pilots, each with an ILS approach and a quick reloading of the flight plan in the FMS, all handled by our Entry Into Service (EIS) pilot. Then I got into the seat with a reload of the flight plan to KBED. The FMS loaded with a speed of 160 knots and altitude of 180 feet. Try as we might, we couldn't change that. Our EIS pilot called all the experts and all we heard was "we've never heard that one before." Finally someone suggested pulling and resetting the MAU circuit breakers. That worked, but I told the EIS pilot, "let's never do that again."

We flew the airplane to KBED for my third landing in the jet. All was good. Then off to KIAD, still good. Back to KBED, still good. The 160 knots / 180 feet reload remains a mystery. So far I have had four takeoffs and landings, my partner four more. So far every landing in the airplane I've witnessed was what we in the G450 world would call perfect: on speed, in the touchdown zone, smooth. I am going to like this airplane.

Entry Into Service - Day 2

22 Feb 2020

The previous night we got a chip detector message so we inspected that in the morning, delaying our start a little.

Pratt & Whitney recommends and will pay for a complete oil system flush between 50 and 100 hours, replacing the oil and the oil filter.

We flew off to Memphis for some barbecue. We did some more maintenance training and then called it a day.

Entry Into Service - Day 3

23 Feb 2020

On day three we went to Teterboro because we are drawn to it like moths to a light bulb, we can't help ourselves. The FMS once again, defaults to 160 knots but this time to 1050' altitude. We powered down to black, brought it back to life, and things worked as they should.

We flew on to Atlanta Peachtree for some lunch but left the aircraft powered as we re-planned for St. Petersburg Clearwater. Again the FMS forced us to 160 knots but this time only 60 feet. So we did the power down routine again. After that leg, our plan was to return to Bedford for a pending trip and now the FMS took us back to the 160 knots and 180 feet:

That's when we realized the error happened during all but one FMS flight plan change with the power never shut down since the last landing, the speed was always 160 knots, and the altitude was always the threshold crossing height of our planned destination. The next day's trip canceled so we called it a night and stayed at KPIE.

Entry Into Service - Day 3

24 Feb 2020

We had another robust day of flying planned, four legs in all. I made the mistake of letting my boss know I wasn't feeling well (headache and sore throat) and she was worried about the Coronavirus. I assured her that if it was anything, it was more likely to be the Dos Equis Virus. Well that was the wrong answer and she ordered me home to bed. Oh well.

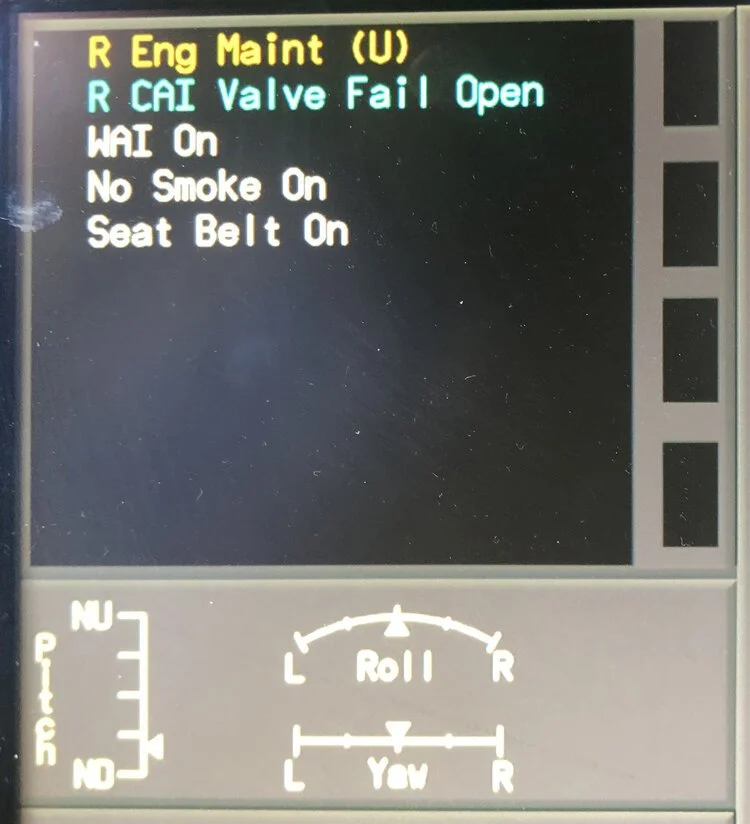

On the way home, while climbing out in clouds at the appropriate temperature we turned the Cowl Anti-Ice (CAI) on. A few minutes later we got the following CAS message:

Sure enough the right engine CAI was around 55 psi. At that moment we popped out of the clouds so we turned the CAI off in accordance with the AFM. We sent our EIS pilot home and scheduled several days of maintenance with the EIS mechanic. We had a handful of interior squawks, the FMS issue, and this CAI Valve.

Entry Into Service - Day 4

25 Feb 2020

As I lay in bed, sidelined by what appears more likely to be the Modelo Especial Virus, the maintenance team went to work replacing the CAI valve and reloading software.

While the airplane is beautiful inside and out, it is hard to imagine it as being "battle ready." The EIS period is five days for the pilot and ten days for the mechanic. Those look like good recommendations to me.

As I write this we still don't know for sure what is causing the 160 knots FMS issue. If you have seen this, please let me know!

Postscript to the FMS Issue

As I write this I haven't tried these solutions, but I will. It appears our problems are common to the fleet given certain conditions on a quick turn. I'll try to isolate those conditions. The proposed solutions include:

Switching the nav source back to FMS 1 & 2, as appropriate, taking FMS nave sources out of NAV 1 & 2. Then hit TOGA.

If that doesn't work, try loading a new cruise altitude in the Perf Init then put the cruise altitude you want back in.

If that doesn't work, try going to manual speeds, spinning something in there, then back to auto speeds.

Also, make sure you're uploading a recall into the FMS before doing any Perf Init or Takeoff Init computations. That should also prevent the CYAN TO/GA Fixed Pitch CAS from manifesting. If you do see that one, load a new cruise altitude then go back to what you actually want for the cruise altitude in the Perf Init.

Another Postscript to the FMS Issue

I am impressed at how our users knew how to deal with this even as the test crews at Gulfstream did not. So far this has happened to me one more time and pressing TO/GA after the new flight plan was loaded instantly cured the problem.